Today, one has the opportunity to visit Petrolimex Saigon is delighted at the enormous changes in many activities of the Company after 40-year establishment and development. It’s seen most clearly in the technical infrastructure investment and application of advanced management models. To understand this process better, Vietnam Trade and Industry Review has an interview with Mr. Do Kim Ma - Manager of Petrolimex Saigon Safety and Environment Technology Department, who has been attached with the Company for many years.Dear readers, we are pleased to represent!

| Mr. Do Kim Ma - Manager of Petrolimex Saigon Safety and Environment Department |

Q: Sir, this year,Petrolimex Saigon has 40th anniversary of its founding.As a senior employee who attached with the Company for many years,would you please tell us about the achievements of Petrolimex Saigon in recent years?

A: The 40-year journey of Petrolimex Saigon construction and development associated with the growth of Vietnam National Petroleum Group (Petrolimex), with each stage of the Country development, innovation and integration.

During that journey, Petrolimex Saigon has always been completing the assigned tasks: maintaining the leading role in organizing for business activities of petroleum and petrochemical products, an important contribution to promoting socio-economic development, ensuring national defence and security, maintaining the market stability in Ho Chi Minh City and the Southern provinces; constantly investing to modernize the system of technical infrastructure; developing human resources and successfully pioneering the application of advanced standards for risk management, improving productivity and increasing efficiency in production– business activities.

Q: Sir,Today,Petrolimex Saigon is being known for taking investment in modern technical infrastructure and equipments, application of advanced management models as key factors of success.Could you please tell the specific things in the process of scientific and technological innovation within 40 years at Petrolimex Saigon?

Petrolimex Saigon was established on September 17th,1975 including Nha Be Oil Terminal, from old facilities of three petroleum companies, they are: Esso, Shell and Caltex, with a total capacity 250,000 m3 and 6 import-export wharfs. After the date of its reunification on April 30th1975, for the US embargo, the country's economic difficulties were numerous. The equipments were reused and replaced by some of Soviet Union, China. It’s starting when the country entered into a period of renewal in 1986, by that Petroleum industry had strong innovation, infrastructure investment being upgraded, renovated, modernized and applied many new science and technology advances.

I would like to point out the application process of science-technology and new equipments at petroleum warehouses and stations of Petrolimex Saigon within 40 years as follows:

At the petroleum warehouses, in the past, the whole old tanks were built on the cajeput pile and sand bet foundation. After using, tanks were sunk deeply and inclined subsidence, causing safety risks by deformation then cracking bottom tanks and bulging roof, risking petrol leak causes high-explosive capability. Since 1997, the Company has started testing the concrete pile foundation construction by pressing, ensuring that no tank is inclined subsidence and increasing capacity to 10,000 m3, 12.000 m3 and the largest is 16,000 m3, eliminating the risk of inclined subsidence and petrol leak of tanks, which cause huge petrol losses.

Before 1975, at oil terminal, there was 01 small tank with capacity of 1.000 m3with the float roof structure for storing petrol. Since 1997, realized the obvious need to protect the environment and reduce petrol loss because of volatile state, the Company has installed floats for gasoline tanks and then some of KO, DO, Jet A1 tanks. So far, at Nha Be Oil Terminal, 23 tanks has installed floats on 72 tanks. By calculations and the actual measurement, for 10,000 m3tanks, if we install floats when it’s filled and in high temperature, a day we can reduce 700 liters of lost petrol than in tanks that were installed petrol automatic measuring equipments, petrol spill alert. This is an advanced automation equipment to control petrol level, petrol temperature and petrol spill in tank alert. This equipment has reduced the petrol measuring by hand, brings accuracy and less strenuous work for people.

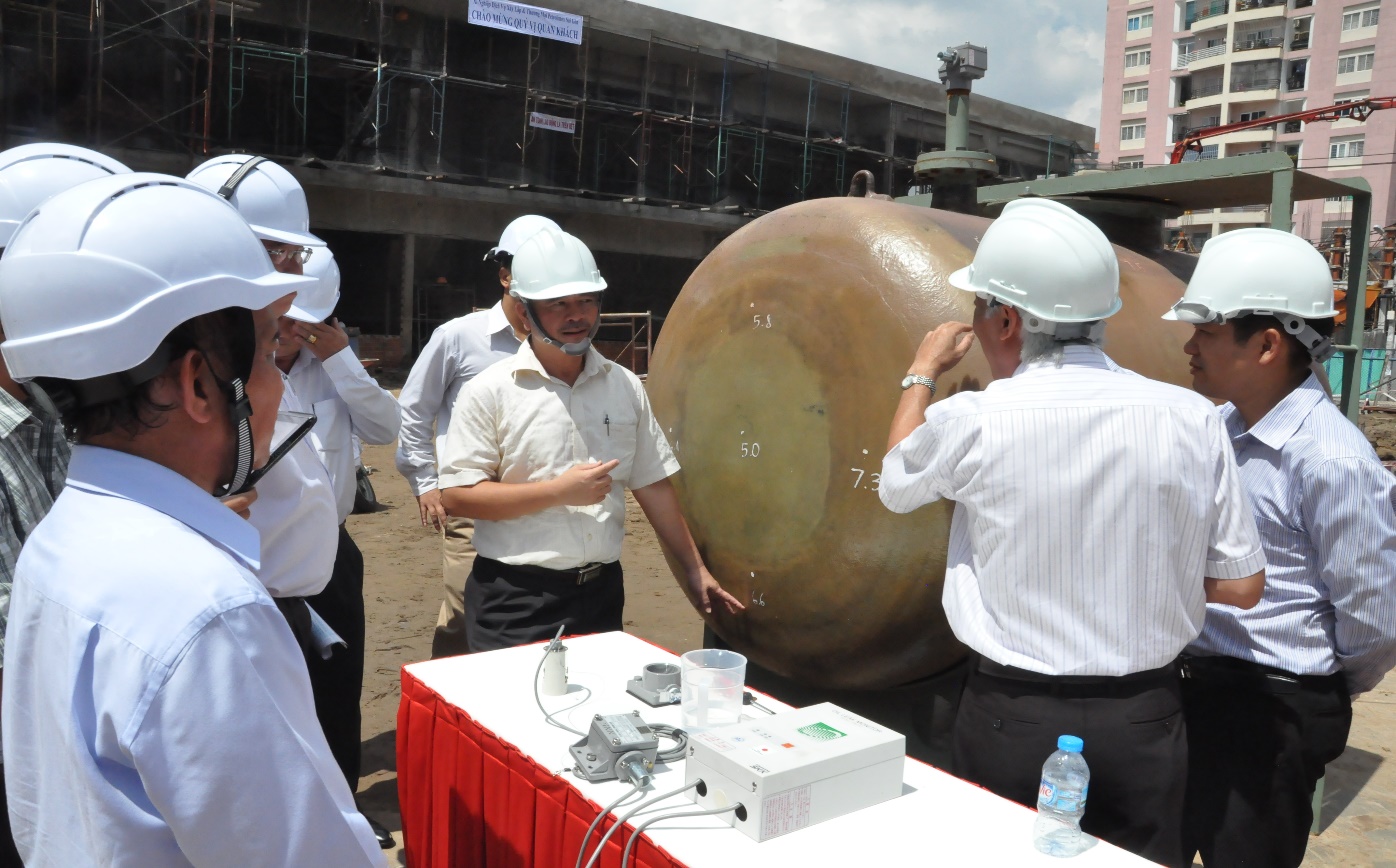

The Unit designs, constructs and uses test pressures to prepare toinstallation of 2-layer tankatPetroleum Station No.11

Secondly, about the technology of petroleum im-export. Since 2005, the Company has installed the first petroleum export cranes for 1A wharf then 4B, 2C wharf and warehouse A (1998-2005), to operate the export crane just need 2 workers instead of dozens of workers . Thus, using export cranes instead of soft pipes reduces number of operators, more safe and tidy for the wharfs. Also, in 1994, the Company began to install electronic flowmeter in warehouse C, followed up by warehouse B (1998) and warehouse A (1999) with high accuracy and good evaluation from customers; Installed the system of tanks and mixture for E5 petrol; Installed petrol stiring equipment; Installed vapour recovery equipment for the roadway export area...

Thirdly, being aware of the importance of fire prevention for the petroleum warehouses and stations, to ensure safetiness in production and business activities is priority task because petrol has high risk of explosion. For fire prevention, in Central Laboratory Department, the Company offers installation of fire alarm system, in the area of roadway export, installing the camera connects to fire alarm control center. To be always ready, along with 07 fire pump stations are located at 03 warehouses (A, B, C) to fire-fight for the whole Nha Be Oil Terminal, installing Cooling Systems, Foam Fire Exstinguishing Systems at every tank and pump station, im-export wharf and roadway export area. In particular, the installation of Water Fire Extinguishing Monitor and Foam Fire Exstinguishing Systems is the most advanced application that major firms like Shell, BP use.

Petroleum Station No.30 installs seal oil import system,automatic tank measurement andapplies the 5S practice

Fourthly, in oil contaminated wastewater treatment technologies, the Company renovated and invested in wastewater treatment system for each warehouse towards concentrate and tight control of wastewater being discharged to the outside. Until now, the wastewater is under controlled at Nha Be Oil Terminal, meets discharge standards.

In responding to oil spills: with warehouses’ capacity up to 730.000 m3 and cargo about 4.5 million tons / year, the number of ships that import and receive cargoes is increasing day by day. To ensure the safety of oil spill and handle oil spills, fires, explosions, the Company has established an Oil Spill Response Service Team of 20 staffs and 02 ships, thousands meters of fixed and movable floats, oil spill suction devices underwater and on land. Whenever a ship enters and receives cargoes, turning floats are scattered around and be ready for troubleshooting as the approval plan of Ho Chi Minh city. At petroleum stations, one of the new technologies was applied effectively was seal oil import system installations and electronic pumps, automatic oil measuring equipment; Installing seal petroleum import system, automatic tank measurement equipment at all 65 stations to minimize the amount of petrol vapor escaping from valves, ensuring environmental safety and reducing the risk of fire; Replacing the entire mechanical pumps with electronic pumps for accuracy purpose, ensuring customer benefits and while networking in the EGAS-ERP project to manage in the stations focusing and more precise.

Besides, the application of new technologies has changed the management of production and business operation activities of the Company as ISO, OHSAS, 5S and most recently, ERP management software for the petrol warehouses and EGAS-ERP for Petroleum Stations, bringing tremendous efficiency in the whole company.

Q: As a senior employee in the Company's science and technology field, could you please share your opinions about the science and technology development orientation of Petrolimex Saigon in near future?

First of all, the innovation process of science & technology together with applying modern equipments are affirmed to be always along with production & business activities of the Company, so makes great contribution to the success of Petromilex Saigon today. Along with the ongoing development of the Company, the innovation of science & technology process is never stop going on, at the same time the employees that are working in science and technology of the Company have grown in numbers, professional, political and ideological steadfastness. The staff and engineers have many important contributions in the results of testing and applying in anti-spill field, overcoming oil spills, anti-volatile petrol, antistatic in during the petroleum import-export process, applying gradually automation and computerization in the petroleum import-export-delivery process to ensure the safeness, accurate measurement; procedures, documents and data more quickly, more accurately, ... thereby contributing to the efficient production and business.

It can be said that the science and technology investment of Petrolimex Saigon is going on the right direction, effectively. To promote the achievements, in near future, Petrolimex Saigon will continue to care, create more favorable conditions in research, offering innovative solutions, applying science - technology into production and business as well as explosion prevention, ensuring environmental and direct-workers’ safety, bringing the practical effect and further to the Company.

Q: Well, thank you for this interview!